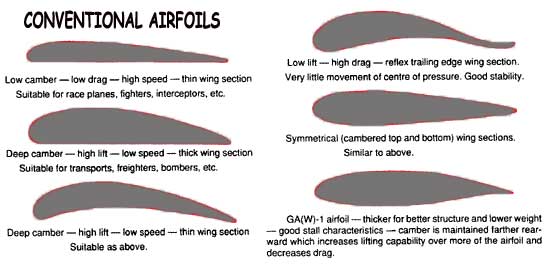

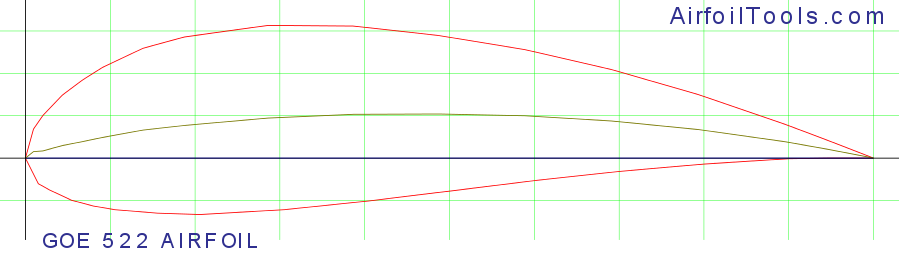

I removed the MDF and placed it aside and clamped in the plywood, with the same 1/8" bit I bored out the 8 holes in the hub. I bore out the four 1/4" holes in the MDF for the fixture. With the MDF clamped down in the CNC with the 1/8" bit in the spindle, I centered and zeroed out my CNC and bit in the center of the wood according to the WCS in the setup for the tool paths. I split up and or grouped the post processes for the 2 different bits. I generated G-Code using the post process function within Fusion 360. I have also included the Fusion 360 file of my model and CAM to see how I actually did it. Added some fillets, extruded the holes in the hub using the first sketch. Then used the circular pattern to create the other half. Then I used the loft function to create the body from each sketch of each offset plane and with a little trimming at the end, I had a half a prop. Since the prop is 24" long or 12" from center to end, I set up 10 offset planes at every 1.2", created a sketch of the airfoil, with rotation for pitch available in the Add In tool on each offset plane. This gave me a realistic airfoil design to the prop, although I took some artistic liberties near the hub.įirst, I found a front view of a prop on line, inserted it as a canvas then used the fit point spline sketch tool to draw am outline of the prop. The DAT file I used was of a NACA4412 propeller off the website. I used the "Airfoil DAT to Spline" Add In. It sounds like the start of a fun project.I'm by no means an aerospace engineer, LOL. Then if just buying one is what you're after, you'll know what the airfoil should look like to get the performance you're after. How will that affect your performance ? Would a different airfoil work better at that thickness ? Profili and Xflr5 can give you an estimate to base your decision on.

For instance you've selected one of the wind tunnel airfoils that he has developed but for structural reasons you need to have it thicker.

You can then enter those ordinates into Profili, Xfoil, or Xflr5 to compare and modify if you need to. There's a database of about 2000 airfoils to get you started. It's available online in many formats from the University of Illinois Department of Aerospace Engineering. We all owe him a great deal for the advancements and knowledge available from that work.

Propeller airfoil how to#

this is a bit of a worst-case scenario because it will be time-consuming and inaccurate but if you have suggestions on how to do it well I would be appreciative.ĭR Michael Selig (who does frequent this forum on occasion) has done an enormous amount of research and development on low reynold's numbers airfoils including airfoils specifically for wind turbines. I have some ideas for this but none are really great. It is also possible to try to measure or trace the airfoil. so that is not really going to work for me. I know helicopters can have symmetric blades but they lack most of the characteristics of normal propellers like twist, changing chord, etc. So onto the main question, Does anyone know where I can get any propellers with their airfoil data included?Ī symmetric airfoil propeller would also be much better for efficiency so if anyone could point me in the direction of finding some symmetric propellers that would be great.

One of the main goals of the projects is to buy "common" propellers rather than having to make my own. I am not particularly picky about what propeller I can use so anything is a good start. It seems that manufacturers like to keep this information secret which is understandable but really sucks for what I'm trying to do.

For proper modeling, I need to know what airfoils the propellers are using along with other geometry like chord distribution (though that is easy to measure by hand). I am doing some research on using propellers like a wind turbine to generate electricity.

0 kommentar(er)

0 kommentar(er)